Unlocking Efficiency and Precision with Industrial Label Printers Thermal Transfer

In today’s fast-paced industrial landscape, the demand for high-quality, durable, and precise printing solutions is higher than ever. Among the myriad options available, industrial label printers thermal transfer stand out as a cornerstone technology that empowers businesses across various sectors. Whether you're in manufacturing, electronics, logistics, or electronics industries, understanding the power and versatility of thermal transfer printing is crucial to staying competitive and delivering superior product identification.

What Are Industrial Label Printers Thermal Transfer?

Industrial label printers thermal transfer are specialized printing machines designed to produce durable, high-resolution labels suitable for harsh environments. Unlike direct thermal printers, which use heat-sensitive paper, thermal transfer printers employ a heated ribbon to transfer ink onto a variety of surfaces, including plastics, metals, fabrics, and other rugged materials. The result is a print that exhibits exceptional longevity, resistance to chemicals, abrasions, moisture, and extreme temperatures.

The Mechanics Behind Thermal Transfer Technology

Understanding the core mechanics of industrial label printers thermal transfer is essential to appreciate their power and versatility. These printers use a combination of components:

- Print Head: The component that heats up and selectively melts the ink from the ribbon onto the label surface.

- Ribbons: Typically made of wax, resin, or a combination, ribbons carry the ink that is transferred during the printing process.

- Media (Labels): The colored or transparent label materials on which the images and text are printed, often made of durable plastics or other resistant materials.

- Transport Mechanism: Ensures precise movement of labels and ribbons through the print head to achieve sharp images and text.

The process involves the print head heating specific areas of the ribbon, which then transfers the ink onto the label surface, creating clear, long-lasting images and text. This process is highly customizable, accommodating different ribbon types and label materials to suit specific industrial needs.

Advantages of Using Industrial Label Printers Thermal Transfer

1. Exceptional Durability and Resistance

Labels produced with industrial label printers thermal transfer are known for their superior resistance to chemicals, oils, UV exposure, and harsh environmental conditions. This durability makes them ideal for product labeling in manufacturing plants, warehouses, and outdoor applications.

2. High-Resolution Printing Capabilities

The technology supports printing at high resolutions, often up to 600 dpi, allowing for detailed barcodes, small fonts, and complex graphics essential in electronics and high-tech industries.

3. Wide Range of Material Compatibility

From paper to polypropylene, polyester, and even metallic foils, thermal transfer printers handle various media suited for different applications, providing unmatched flexibility in label design and placement.

4. Cost-Effective for Bulk Production

Once set up, thermal transfer printing reduces waste and increases output speed, making it highly suitable for large volume production runs. The durability of the labels also means less re-labeling or maintenance in the long run.

5. Environmentally Friendly Options

Many modern ribbon formulations are eco-friendly, and the technology supports sustainable practices by reducing waste and energy consumption during operation.

Applications of Industrial Label Printers Thermal Transfer in Different Industries

Printing Services Industry

Businesses providing printing services leverage industrial label printers thermal transfer for creating custom labels, packaging identifiers, and promotional branding materials. Their ability to produce high-quality, durable labels makes them a preferred choice for clients requiring longevity and reliability.

Electronics Sector

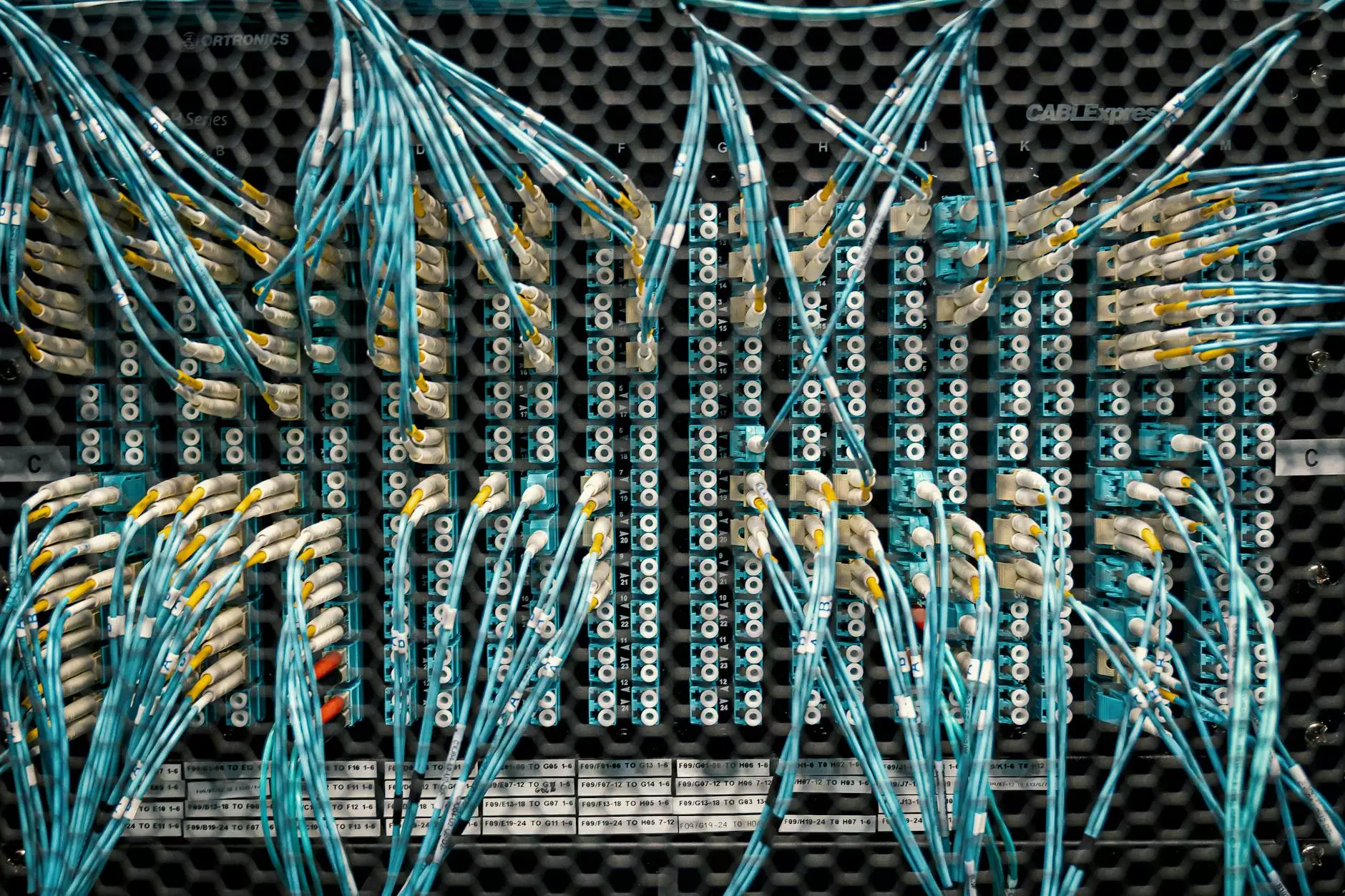

Electronics manufacturers rely heavily on thermal transfer printing for clear, precise labeling of circuit boards, components, and cables. The high resolution and chemical resistance ensure that labels remain legible and intact even in the most demanding environments.

Computer and Data Management Industry

In the context of computer hardware and data management, clear and durable labels are critical for inventory control, asset management, and product identification. Industrial thermal transfer printers provide the consistency and reliability needed to keep these systems running smoothly.

Selecting the Right Industrial Label Printer for Your Business

Consider Your Application Needs

- Label Durability: Will labels be exposed to chemicals, moisture, or extreme temperatures?

- Print Resolution: Is high-resolution printing essential for detailed graphics or tiny barcodes?

- Volume: What is your expected volume of labels per day or month?

- Material Compatibility: What type of media will you use—PVC, polyester, paper?

- Speed Requirements: Do you need high-speed printing for large batches?

Research Leading Brands and Technologies

At OmegaBrand, we prioritize innovation and quality, offering industrial label printers thermal transfer built with cutting-edge features such as modular design, user-friendly interfaces, and advanced connectivity options. Ensuring you choose a reliable brand guarantees seamless integration into your existing workflows.

Enhancing Business Efficiency with OmegaBrand's Industrial Label Printers

OmegaBrand specializes in delivering top-tier industrial label printers thermal transfer systems tailored to your business requirements. Our printers are designed to optimize productivity, reduce costs, and ensure high-quality outputs. Here are some ways OmegaBrand's solutions can boost your operations:

- Customization: Automate complex labeling requirements with flexible customization options.

- Reliability: Experience minimal downtime and maintenance with high-quality, durable components.

- Integration: Compatible with existing enterprise systems for seamless data management.

- Support & Service: Our dedicated team provides comprehensive support to maximize your printer’s lifespan and efficiency.

Emerging Trends in Industrial Label Printing and Thermal Transfer Technology

Smart Labels and RFID Integration

The industry is rapidly adopting smart technologies, where thermal transfer labels integrate with RFID chips, enabling real-time tracking and automated inventory management. This integration enhances traceability, compliance, and operational transparency.

Eco-Friendly Ribbons and Materials

With increasing environmental awareness, manufacturers are developing biodegradable ribbons and recyclable labels without compromising durability or print quality. OmegaBrand is committed to sustainable solutions that align with global eco-initiatives.

Automation and IoT Connectivity

Next-generation thermal transfer printers come equipped with IoT features allowing remote monitoring, automated maintenance alerts, and software-driven adjustments, ensuring optimal operation without constant manual oversight.

Why Choose OmegaBrand for Your Industrial Label Printer Needs?

OmegaBrand stands out by offering:

- Premium Quality: Only the highest-grade components ensure long-lasting, reliable performance.

- Cutting-Edge Technology: Incorporation of latest innovations like high-resolution printing, wireless connectivity, and smarter ribbons.

- Customization & Flexibility: Tailored solutions for specific industry challenges and production scales.

- Dedicated Support: Technical assistance, training, and ongoing service to keep your systems at peak performance.

Conclusion: Embracing the Future of Industrial Label Printing with Thermal Transfer Technology

In an era where precision, durability, and efficiency are vital for maintaining competitive advantage, industrial label printers thermal transfer emerge as an indispensable tool for modern businesses. By leveraging this technology, enterprises can produce labels that withstand rigorous conditions, convey accurate information, and streamline operational workflows. OmegaBrand remains committed to providing state-of-the-art solutions that empower industries to excel and innovate continuously.

Investing in high-quality thermal transfer printing systems is not just a technological upgrade—it's a strategic move towards sustainable growth, enhanced productivity, and uncompromised quality. Discover the difference with OmegaBrand and elevate your business to new heights today.